Health and Safety Software » Health and Safety Software News » PPE Management » Working with Electrical Equipment

Working with Electrical Equipment

Health and safety when working with electrical equipment is essential to prevent accidents, injuries, and fatalities. Below are some key considerations to keep in mind when working with electrical equipment.

- Use Personal Protective Equipment (PPE): PPE such as insulated gloves, safety glasses, and hearing protection can help protect you from electrical hazards.

- Perform regular equipment maintenance: Regular inspection and maintenance of electrical equipment can help prevent breakdowns and reduce the risk of electrical fires and explosions.

- Use appropriate tools and equipment: Always use the right tools and equipment for the job, and ensure they are in good condition before use.

- Implement electrical safety protocols: Follow established electrical safety protocols such as lockout/tag-out procedures and ensure that electrical equipment is de-energized before maintenance.

- Maintain proper ventilation: Electrical equipment can produce hazardous fumes, so ensure proper ventilation is in place in order to prevent respiratory issues.

- Keep the work area clean and clear: An organised work area reduces the risk of trips and falls, which can lead to electrical accidents.

- Complete electrical safety training: Ensure you have received adequate electrical safety training, and always follow the recommended safety procedures and guidelines.

By following these tips, you can help ensure the health and safety of yourself and those in close proximity when working with electrical equipment.

Arrange your demonstration

Let us show you how we can transform your health and safety, risk and compliance management

Please choose a date and time for your demo. We look forward to meeting with you.

Latest Updates & Information

Boost Safety & Efficiency With Digital Permit to Work Software

Permit to Work software helps organisations manage high-risk tasks safely and compliantly. Discover how iProtectU’s

Achieving ISO 45001 with an Integrated Audit-Led QHSE Software Platform

Achieving ISO 45001 doesn’t need to be complex or resource-heavy. The real challenge isn’t understanding

Transform Workplace Training with Smarter eLearning & Training Management

Discover how eLearning and training management software helps organisations deliver, track and optimise workplace safety

A Very iProtectU New Year’s Tale – From Compliance to Continuous Confidence in 2026!

As we step into 2026, it’s time to embrace a smarter approach to safety. Discover

Twas the Night Before Compliance: A Very iProtectU Christmas & New Year’s Tale

Ho ho hold on – before you climb that ladder to hang the fairy lights…

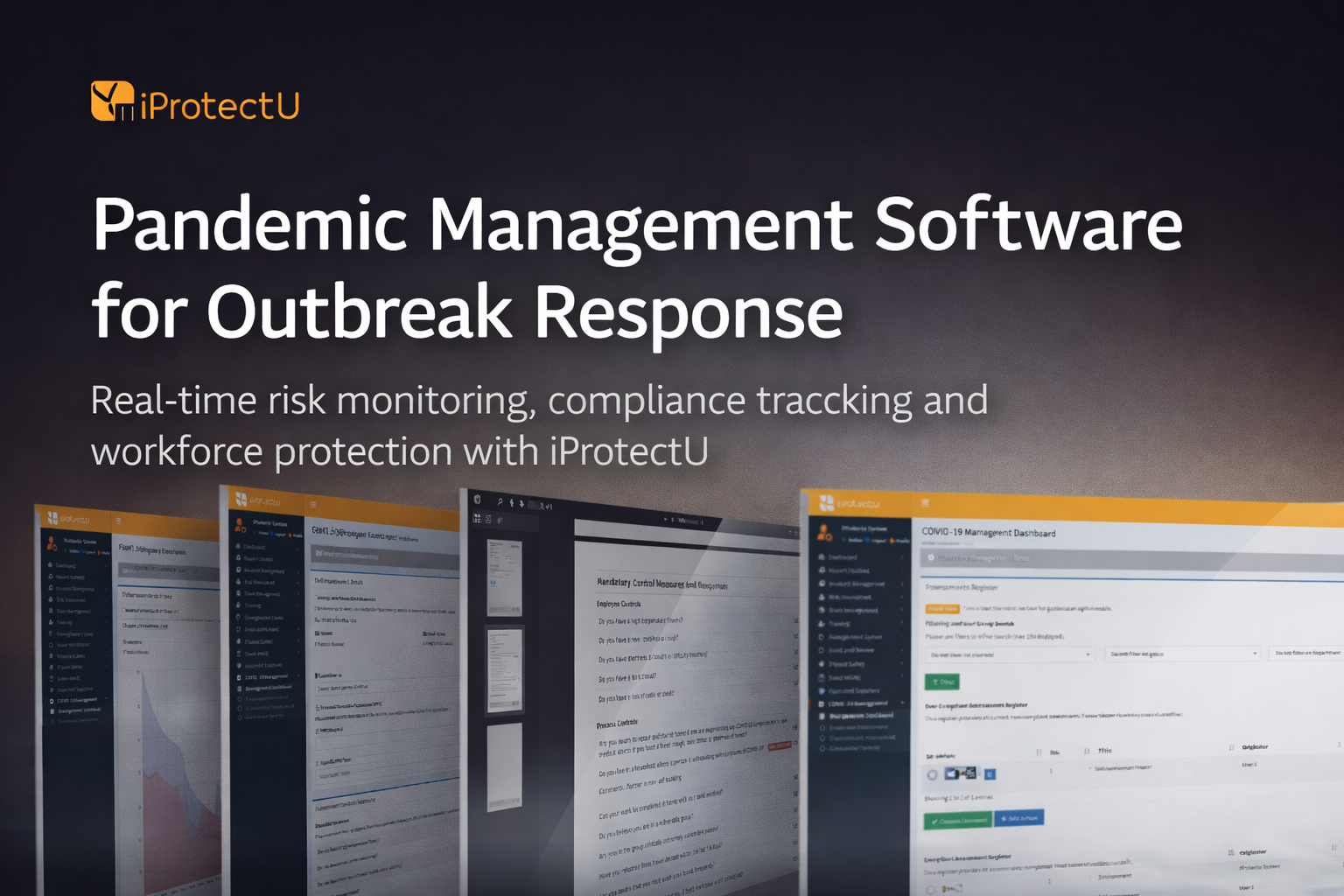

How Pandemic Management Software Helps Organisations Respond to Europe’s Escalating Flu Outbreak

Europe’s rising influenza activity underscores the importance of having the right digital tools in place.