As a business, you must be knowledgeable about the main risks and the steps you need to take to manage them responsibly. Generally, you need to do everything ‘reasonably practicable’ to protect personnel from harm. This means balancing the level of risk against the measures needed to control the real risk in terms of money, time or trouble.

The identified risks should be reduced to the lowest reasonably practicable level by applying control measures, in the form of a risk management process, in order of priority.

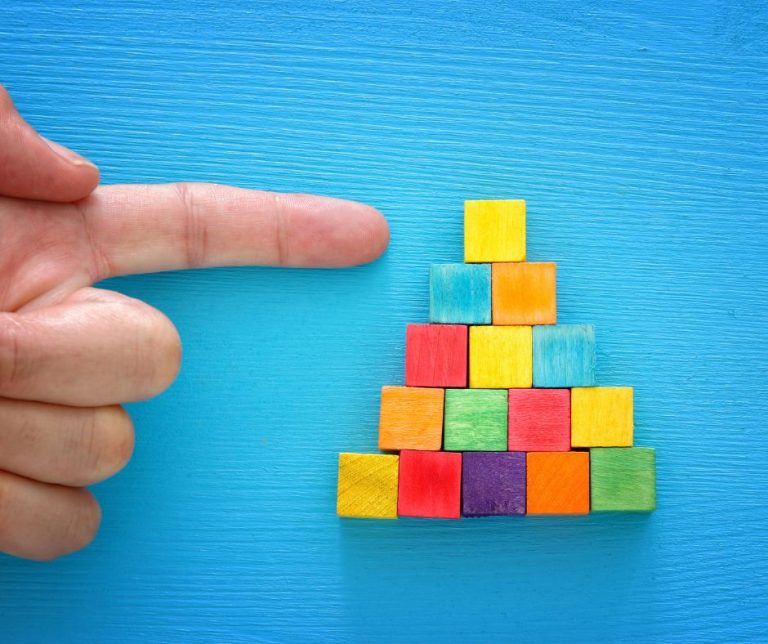

The Hierarchy of Risk Control: Five Levels

The hierarchy is made up of five levels, ranging from the most to the least effective:

- Elimination: The most effective control measure involves eliminating the hazard and associated risk. An example might be removing a working at height risk by conducting the work at ground level.

- Substitution: If elimination is not an option, substitution involves replacing the hazardous substance or process with a less hazardous alternative. For example, replacing a solvent with a water-based solution.

- Engineering Controls: These are physical or mechanical measures that isolate or control the hazard at the source. Examples may include installing ventilation systems to remove hazardous fumes and using safety guards on machinery.

- Administrative Controls: These involve changing the way work is performed, managed, or organised to reduce exposure to hazards. Examples include developing safe work procedures and implementing lockout/tagout procedures.

- Personal Protective Equipment (PPE): This is the last resort in the hierarchy, as it simply provides a barrier between the worker and the hazard. PPE includes safety glasses, gloves, headwear respirators, and other protective gear.

Putting the Hierarchy of Risk Control into practice

Ensure thorough hazard identification. Identifying all potential hazards present in the workplace is crucial.

Conduct a rigorous risk assessment. Once hazards are identified, they must be assessed for their severity and likelihood of occurrence.

Select suitable controls. Based on the risk assessment, appropriate control measures from the hierarchy should be selected.

Implement and monitor effectively. The selected control measures must be implemented and effectively managed. Regular monitoring is essential to ensure their continued effectiveness.

Provide employee training. Employees must be provided with comprehensive training on workplace hazards, the implemented control measures, and their role in maintaining safety.