Streamlining PUWER, LOLER & work/lifting-equipment safety in one place

Your Equipment Deserves More Than a Spreadsheet.

Every time a sling, fork-extension or hoist goes into use, there’s a world of risk behind it. From legal obligations (for example under Provision and Use of Work Equipment Regulations (PUWER) to Lifting Operations and Lifting Equipment Regulations (LOLER)) to maintenance, operator competence and defect tracking.

Too many organisations still keep these checks in spreadsheets, binders or (worst of all) in people’s heads.

Here’s where a dedicated digital system can change this:

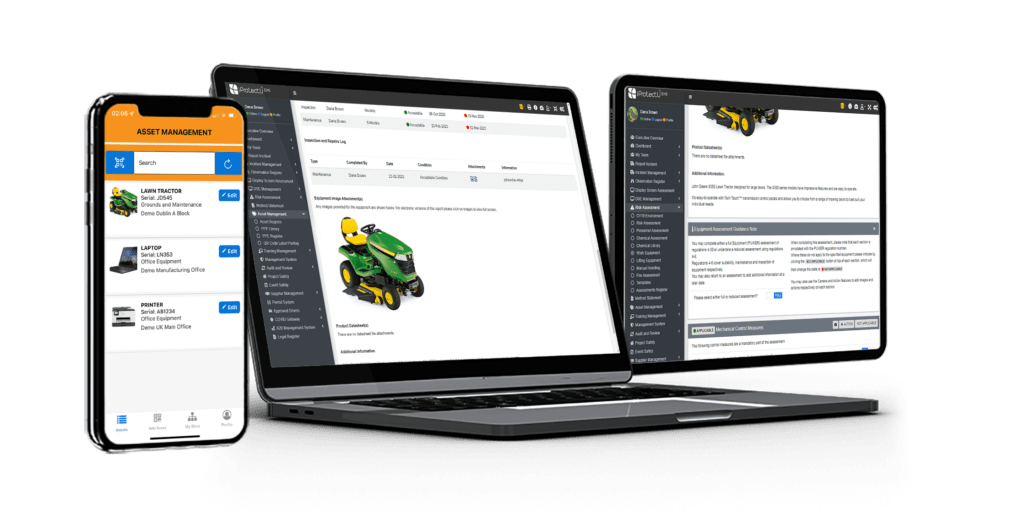

linking asset registers, assessments, inspections and evidence in one seamless flow.

The traditional pain points

- Equipment scattered across sites, each with its own service history, owner and inspection status.

- Pre-use checks done on paper or verbally, often with issues slipping through the cracks.

- Thorough Examinations and certificates stored in filing cabinets or as PDFs with no live tracking of expiry or overdue tasks.

- Little visibility of hotspots: which classes of equipment are underperforming or most at risk?

- Compliance audits become stress-fests rather than routine business.

A modern digital workflow using iProtectU software

Here’s how a typical workflow looks:

Asset register – import or create items (cranes, MEWPs, conveyors, slings, etc), capturing ID, make/model, location, owner.

Link the risk assessment – launch your PUWER (for work equipment) or LOLER (for lifting equipment) assessment from the asset record. Pre-populated data saves time.

Schedule inspections – pre-use checks, weekly/periodic, thorough examinations with reminders built in.

Raise actions/defects – when things fail, record the defect, attach photos, assign corrective action.

Store evidence – manuals, certificates, maintenance records, photos all attached to the asset record.

Dashboards & reporting – compliance status by site, asset class, risk levels; export to PDF/CSV if needed.

Why this matters (benefits)

Safer operations – fewer defects, fewer surprises in use of equipment.

Proven compliance – clear audit trail, version-controlled PDF outputs, evidence stored.

iProtectU Health and Safety Software

Time saved – remove the hassle of manual tracking, spreadsheets, missed deadlines.

Insights & trends – spot high-risk equipment classes, see overdue actions, visualise status across sites.

Mobile & offline ready – if operators are out on site in remote areas, they can still use the system; drafts save, sync when online.

What equipment & regulations are covered

Examples of equipment: cranes, MEWPs, forklifts, hoists, slings, shackles, beams, man-baskets; plus machine tools, conveyors, mobile plant, power tools, pressure systems.

Regulations & standards:

- LOLER (lifting accessories/Examinations);

- PUWER (safe use of work equipment);

- Work at Height Regulations where relevant;

- Alignment with ISO 45001.

Practical steps to get started

- Audit your current asset register: what equipment do you have, when were the last inspections?

- Identify the highest-risk equipment classes (lifting gear, mobile plant, etc) and prioritise migrating those into the system.

- Configure the software (or your team) to capture required fields: owner, location, asset class, inspection dates, etc.

- Roll out training to operators and maintenance staff: emphasise mobile / offline use if applicable.

- Set up dashboards and reports: decide key metrics (e.g., % of assets overdue, number of defects open, inspection backlog).

- Run a pilot for one site or equipment class, review results, then roll out more widely.

- Use exported reports for internal review and external audits: you’ll be able to show your “single source of truth”.

Build a Sustainable Safety Culture

Control the Equipment. Control the Risk. Control the Outcome.

If you’re still wrestling with spreadsheets, multiple systems or paper-based checks, switching to a digital platform for work & lifting equipment risk assessment is more than just “nice to have”, it’s becoming the standard for proactive health & safety management.

With asset-linked inspections, defect tracking, mobile functionality and full audit-trail reporting, you’ll not only reduce risk but also demonstrate compliance with confidence.

Why not book a demo today to see how it could work in your organisation?