Why Chemical Risk Assessment Matters

Here’s the uncomfortable truth

Many organisations still rely on spreadsheets, paper files, or outdated systems to manage their chemical registers and COSHH risk assessments.

It feels “good enough” – until it isn’t.

- Safety Data Sheets (SDSs) go out of date without anyone noticing.

- Assessments get buried in folders and miss review deadlines.

- Real task-based exposures (how chemicals are actually used) never get considered.

The result? Hidden compliance gaps, unnecessary risks to workers, and wasted time on admin that could easily be automated.

According to industry surveys, over 80% of companies fail in at least one aspect of chemical safety compliance. Meanwhile, studies consistently show that spreadsheets contain errors in the vast majority of cases (over 90%), making them a poor tool for managing high-risk processes like chemical safety.

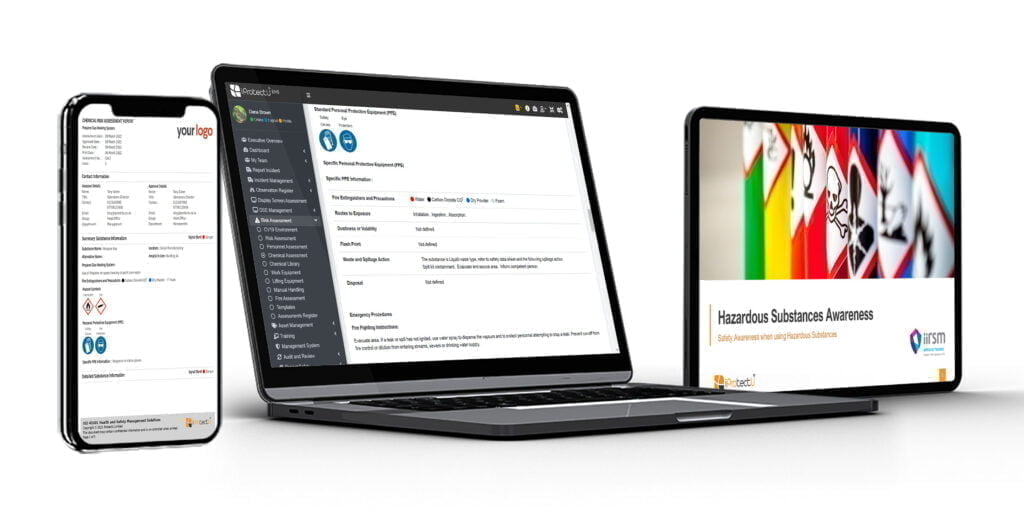

The good news: it doesn’t have to be this way. With iProtectU Chemical & SDS Risk Assessment Software, you can eliminate these common mistakes and transform how your business manages chemical safety.

The Challenge with Traditional Approaches

Before diving into solutions, it’s worth reflecting briefly on the limitations of traditional methods:

- Fragmented data: SDSs, chemical registers, and risk assessments live in different places – often inconsistent and outdated.

- Lack of version control: Hard to track who made changes, when an assessment was last reviewed, or whether the version in use is the latest.

- Time-consuming administration: Chasing overdue reviews, updates, and corrective actions wastes valuable time.

- Poor visibility: Management struggles to see which substances pose the highest risks, where reviews are overdue, or which sites are non-compliant.

These gaps can leave organisations exposed to non-compliance with regulations like COSHH, CLP/GHS, and ISO 45001 – or worse, result in workplace exposure incidents.

How iProtectU Chemical Risk Assessment & SDS Management Solves This

The Benefits in Practice

The iProtectU Chemical & SDS module is designed to close these gaps by bringing all chemical risk management processes into one integrated platform:

- Central chemical register & SDS library

Keep a single source of truth for all substances, linked to up-to-date SDSs, hazard pictograms, and compatibility data. - Task-based risk assessments

Assess chemicals based on how they are actually used – considering exposure routes, frequency, and people affected. - Controls & action tracking

Apply the hierarchy of controls, assign corrective actions, and automate reminders until they’re closed. - Exposure & health surveillance monitoring

Record Workplace Exposure Limits (WELs), schedule monitoring, and link health checks to assessments. - Templates & custom workflows

Use ready-made COSHH templates or configure your own to suit your processes. - Notifications & review scheduling

Never miss a deadline with automated reminders for reviews, SDS updates, and overdue actions. - Evidence & audit trail

Attach documents, photos, and certificates while maintaining a full audit log and version control. - Integration across H&S modules

Connect chemical risk data to incidents, audits, and training records for a complete compliance picture. - Training linkage

Auto-assign IIRSM-approved awareness training and store certificates with automatic refresh reminders. - Mobile & offline support

Complete COSHH assessments in the field, capture photos, and work offline when required.

Benefit | What It Means in Real Terms |

|---|---|

| Stronger compliance | Align with COSHH, CLP/GHS, and ISO standards with evidence to prove it |

| Lower risk | By linking assessments to real-world tasks and enforcing timely reviews |

| Time savings | Automation cuts admin burden and follow-ups |

| Better visibility | Dashboards and analytics highlight gaps and trends |

| Audit readiness | Version control and audit trails make inspections stress-free |

| Engaged workforce | Everyone understands their role and actions in managing risk |

The Lifecycle of a Digital Chemical Assessment

- Register substances and upload SDS.

- Initiate risk assessments linked to specific tasks and users.

- Define & assign controls/actions with deadlines and owners.

- Communicate outcomes with COSHH summary sheets and briefings.

- Monitor & review exposure and health surveillance, keeping reviews up to date.

- Report & analyse trends with dashboards and automated reports.

- Continuously improve by updating when processes or substances change.

Chemical safety is a high-stakes area where outdated methods no longer cut it. Relying on spreadsheets and manual systems leads to missed reviews, outdated SDSs, and compliance blind spots. That’s the mistake many organisations still make.

The smarter way forward is to adopt a purpose-built digital system that eliminates admin overhead, ensures compliance, and provides the visibility managers need to keep workers safe.

With iProtectU Chemical & SDS Risk Assessment Software, you can finally leave the 80% mistake behind — and build a safer, more proactive safety culture.

Dont make the mistakes - build a safer, proactive culture instead

Chemical safety is a critical risk area where outdated methods no longer cut it. Relying on spreadsheets and manual systems leads to missed reviews, outdated SDSs, and compliance blind spots. That’s the mistake many organisations still make.

The smarter way forward is to adopt a purpose-built digital systems that eliminates admin overhead, ensures compliance, and provides the visibility managers need to keep workers safe.

With iProtectU Chemical & SDS Risk Assessment Software, you can build a safer, more proactive safety culture.

Build a Sustainable Safety Culture

Simplify COSHH compliance with iProtectU Chemical & SDS Risk Assessment Software

Book a demo today and discover how easy it is to keep your people safe and your business compliant.